- CR2032 3V battery + battery holder

- ATtiny85 MCU + 8 pin socket

- TMP36 temperature sensor + 3 pin female header

- 315MHz RF TX module + 4 pin female header

- A small amount of tripad board

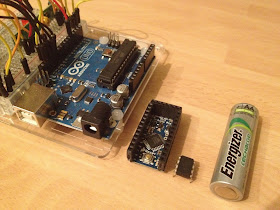

The results without any parts in place looks like this.

And this is what it looks like with all the parts in place.

I'm fairly pleased with how neat the soldering turned out.

Sadly having built this I found that the RF TX no longer worked reliably and the temperature sensor wasn't reporting accurate readings! This required some software fixes!

1) Fixing the RF TX

I have historically used a scheme where I sent three 16 bit values and then combined them at the receiver. However, the Manchester lib now supports sending longer messages so I've retired my pointless message combining code and simply send a single longer message.

2) Getting accurate readings out of the TMP36

The basic method for getting temp readings is as follows.

// Constant: 5000 / 1024

float milliVolts = sensorValue * 4.8828125;

float tempC = (milliVolts - 500) / 10;

return tempC;

The crucial change to make when running on an ATtiny85 is to change the constant which adjusts for the reference voltage being used which in my case is certainly not 5V!

First, add the following to your setup method. This tells the ATtiny85 to use the internal 1.1V reference voltage in preference to the VCC which will change as our battery runs down.

// Select the 1.1V internal ref voltage

analogReference(INTERNAL);

Secondly, update the temp reading code as follows.

int sensorValue = analogRead(TmpPin);

// Constant: 1100 / 1024

float milliVolts = sensorValue * 1.07421875;

float tempC = (milliVolts - 500) / 10;

return tempC;

3) Getting more accurate readings out of the TMP36

The ATtiny85 internal 1.1V reference voltage isn't very accurate so it's worth calibrating the constant you are using. To do this I took a temperature reading from the TMP36 when connected to my ATtiny85 and when connected to an Arduino Uno. I then used the following formula:

V_calib = V_base * ((T_ref + 50) / (T_base + 50))

V_base = 1100

T_ref = temp as measured on Arduino Uno

T_base = temp as measured on ATtiny85

I ended up with V_calib = 1028 which gave me fairly accurate temp readings.

The results?

A working wireless sensor node! (I have added a ~20cm antenna wire since the previous pictures)

I have tested this node briefly but I won't deploy it until I do some more work.

For the wireless sensor node I want to build an enclosure.

For the base station I want to build an enclosure and write code to handle storing readings and allowing download over bluetooth.

As ever, the Arduino code is available on Github: